OEM/ODM Supplier Uv Coating Spc Floor - DIY Click Installation Rigid Core Luxury Vinyl Plank – TopJoy

OEM/ODM Supplier Uv Coating Spc Floor - DIY Click Installation Rigid Core Luxury Vinyl Plank – TopJoy Detail:

Traditional vinyl floors are composed of almost entirely PVC and, at temperatures above 80-90F, start to expand and lose stability. In practice, this has meant that vinyl plank could not be safely recommended in spaces that reach temperatures above 90F or in installations where the longest run was above 35 feet.

We, TopJoy, addressed this issue by reformulating the core of our planks to a majority-limestone composite. By using up to 70% limestone content in the core of our planks, we create the uniquely “rigid” property of our floors. Not only does the high limestone content mean less expansion and contraction to begin with, but it also means that when expansion and contraction does occur the floors can handle it.

Anyone looking for a durable, long-lasting floor that enhances the look of any space and won’t break the bank. Rigid core vinyl flooring are perfect for you!

|

Specification |

|

|

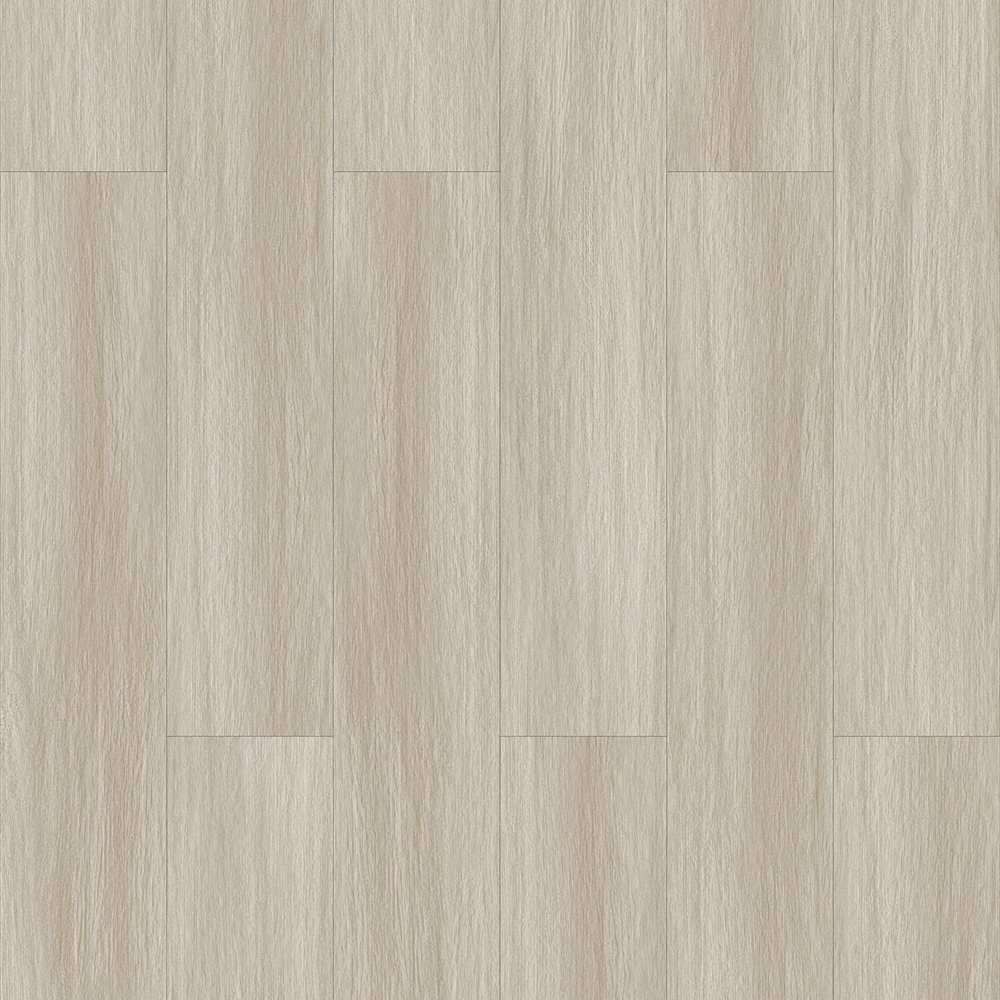

Surface Texture |

Wood Texture |

|

Overall Thickness |

4mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.2mm. (8 Mil.) |

|

Width |

7.25” (184mm.) |

|

Length |

48” (1220mm.) |

|

Finish |

UV Coating |

|

Locking System |

|

|

Application |

Commercial & Residential |

Technical Data:

| SPC RIGID-CORE PLANK TECHNICAL DATA | ||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

Packing Infornation:

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |

Product detail pictures:

Related Product Guide:

Cooperation

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for OEM/ODM Supplier Uv Coating Spc Floor - DIY Click Installation Rigid Core Luxury Vinyl Plank – TopJoy , The product will supply to all over the world, such as: Libya , Bolivia , Jamaica , We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!

实景1.jpg)