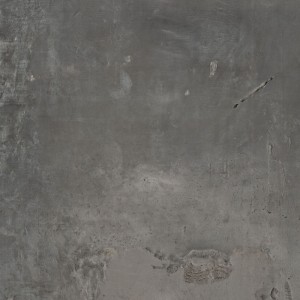

New Trend Industrial Style Cement Concrete Look SPC Flooring

Product Detail:

“Industrial” decoration resonates with people like a more relaxed, modern look. A house furnished in an industrial style is capable of creating a sophisticated contemporary atmosphere that also has a genuine and lived-in feel. Floors should match the rough spirit of the untreated materials. Our industrial style vinyl flooring with a stylish, new, hi-tech solution makes the tiles even more versatile. Environmental friendly SPC flooring captures the essence of the style you desire with its perfect balance of colors, textures, and widths. Floors with a weathered stone look also fit the bill. This style adds warmth and nostalgia to any room. Think about the floors in old factories. That’s what you want to achieve. Compared with the real concrete floors, our TYM508 SPC cement flooring could help you to save a lot of time and labor fees from the processes of the cement floor and give you a warmer foot sense. As our SPC flooring uses a convenient locking system, people could install our floors by the Installation instructions with very little time.

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

4mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.2mm. (8 Mil.) |

|

Width |

12” (305mm.) |

|

Length |

24” (610mm.) |

|

Finish |

UV Coating |

|

Locking System |

|

|

Application |

Commercial & Residential |

Technical Data:

Packing Infornation:

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |