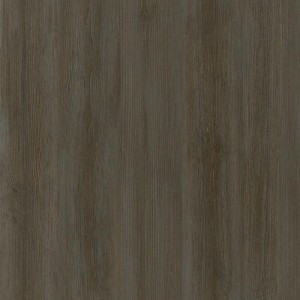

Grey Walnut Super core SPC Vinyl Floor

If you’re looking for high-style, try our super core vinyl flooring. Grey walnut SPC vinyl floor is high-quality, beautiful, and affordable flooring that will make your space look amazing.

It’s specially designed for contemporary residential and commercial areas with the vivid natural walnut grain. In fact, many customers don’t even realize they are looking at vinyl when they see the product - that’s how real it looks. It has better waterproof property, dimensional stability, and durability than real wood flooring. Since the super core vinyl floor is 100% waterproof, it can be installed in wet areas and will never swell when exposed to water. As it’s dimensionally stable, it will not expand or contract under normal conditions.

The optional pre-attached underlay provides excellent sound abatement in households and offices. With zero acclimation time and an easy locking system, you can have a beautiful, natural look waterproof surface in no time!

|

Specification |

|

|

Surface Texture |

Wood Texture |

|

Overall Thickness |

5.5mm |

|

Underlay(Optional) |

IXPE/EVA(1mm/1.5mm) |

|

Wear Layer |

0.3mm. (12 Mil.) |

|

Width |

7.24” (184mm.) |

|

Length |

36” (914mm.) |

|

Finish |

UV Coating |

|

Click |

|

|

Application |

Commercial & Residential |

|

SPC RIGID-CORE PLANK TECHNICAL DATA |

||

|

Technical Information |

Test Method |

Results |

|

Dimensional |

EN427 & |

Pass |

|

Thickness in total |

EN428 & |

Pass |

|

Thickness of wear layers |

EN429 & |

Pass |

|

Dimensional Stability |

IOS 23999:2018 & ASTM F2199-18 |

Manufacturing Direction ≤0.02% (82oC @ 6hrs) |

|

Across Manufacture Direction ≤0.03% (82oC @ 6hrs) |

||

|

Curling (mm) |

IOS 23999:2018 & ASTM F2199-18 |

Value 0.16mm(82oC @ 6hrs) |

|

Peel Strength (N/25mm) |

ASTM D903-98(2017) |

Manufacturing Direction 62 (Average) |

|

Across Manufacture Direction 63 (Average) |

||

|

Static Load |

ASTM F970-17 |

Residual Indentation:0.01mm |

|

Residual Indentation |

ASTM F1914-17 |

Pass |

|

Scratch Resistance |

ISO 1518-1:2011 |

No penetrated the coating at the load of 20N |

|

Locking Strength(kN/m) |

ISO 24334:2014 |

Manufacturing Direction 4.9 kN/m |

|

Across Manufacture Direction 3.1 kN/m |

||

|

Colour Fastness to Light |

ISO 4892-3:2016 Cycle 1 & ISO105–A05:1993/Cor.2:2005& ASTM D2244-16 |

≥ 6 |

|

Reaction to fire |

BS EN14041:2018 Clause 4.1 & EN 13501-1:2018 |

Bfl-S1 |

|

ASTM E648-17a |

Class 1 |

|

|

ASTM E 84-18b |

Class A |

|

|

VOC Emissions |

BS EN 14041:2018 |

ND – Pass |

|

ROHS/Heavy Metal |

EN 71-3:2013+A3:2018 |

ND – Pass |

|

Reach |

No 1907/2006 REACH |

ND – Pass |

|

Formaldehyde emission |

BS EN14041:2018 |

Class: E 1 |

|

Phthalate Test |

BS EN 14041:2018 |

ND – Pass |

|

PCP |

BS EN 14041:2018 |

ND – Pass |

|

Migration of Certain Elements |

EN 71 – 3:2013 |

ND – Pass |

|

Packing Information(4.0mm) |

|

|

Pcs/ctn |

12 |

|

Weight(KG)/ctn |

22 |

|

Ctns/pallet |

60 |

|

Plt/20’FCL |

18 |

|

Sqm/20’FCL |

3000 |

|

Weight(KG)/G.W |

24500 |